Electrolysis mold function, the dirt is produced by the action of electric current to produce positive and negative molecules, through the catalytic action of oxygen and hydrogen generated on the metal surface, the dirt part is quickly decomposed, peeled off and surfaced; using the cavitation effect of ultrasound , Produces countless small bubbles and collides with the object. Impact blasting the dirt on the workpiece to automatically peel off the dirt.

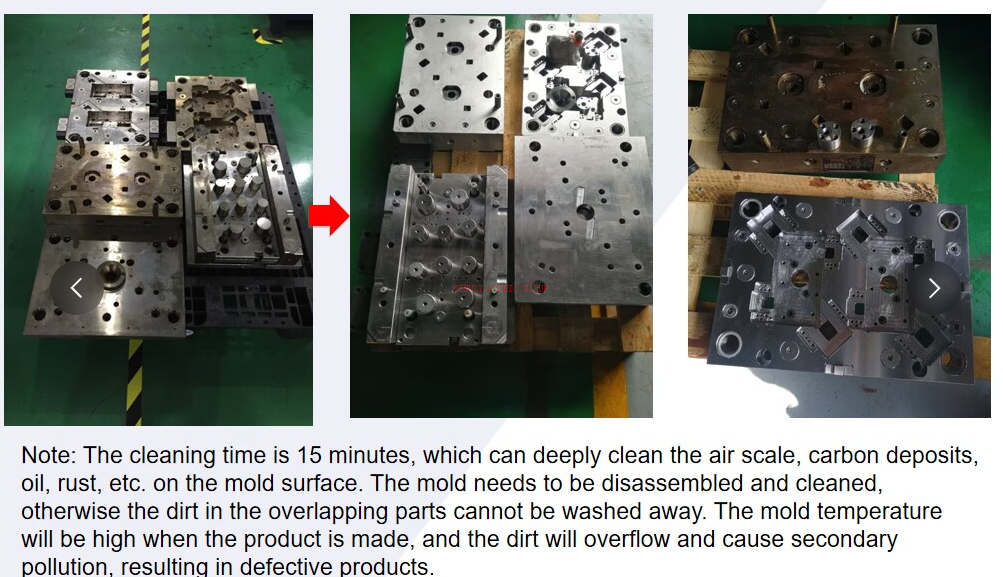

Mold cleaning uses a special solution to quickly decompose the dirt through a sufficient chemical effect. Completely remove any dirt on the surface of the mold, even any mold with a complex shape can remove the dirt, and has a good anti-rust function, which greatly reduces the product defect rate after mold cleaning.

Use the mold or the workpiece to be cleaned as the cathode (just put it in the cleaning frame), and use the standard electrode rod as the anode. The use of electrolyzed water produces oxygen at the anode and hydrogen at the cathode. During the operation process, a large amount of hydrogen is generated on the surface of the workpiece, so that the dirt is quickly decomposed and peeled off from the surface of the workpiece; at the same time, the cavitation effect of ultrasonic waves is used to cause countless small bubbles to collide with the object. Impact blasting the dirt on the workpiece to automatically peel off the dirt.

At the same time, the special cleaning liquid 102C is used to make the dirt decompose rapidly through a sufficient chemical reaction. In this way, even the difficult-to-clean parts, such as the grooves, grooves, corners, holes, holes, bites and other complicated parts inside the mold, will be cleaned cleanly, and the mold will show a brilliant metallic luster from the inside to the outside.

Plastic molds, hardware molds, optical mirror molds, rubber molds, medical equipment, auto parts molds, etc.

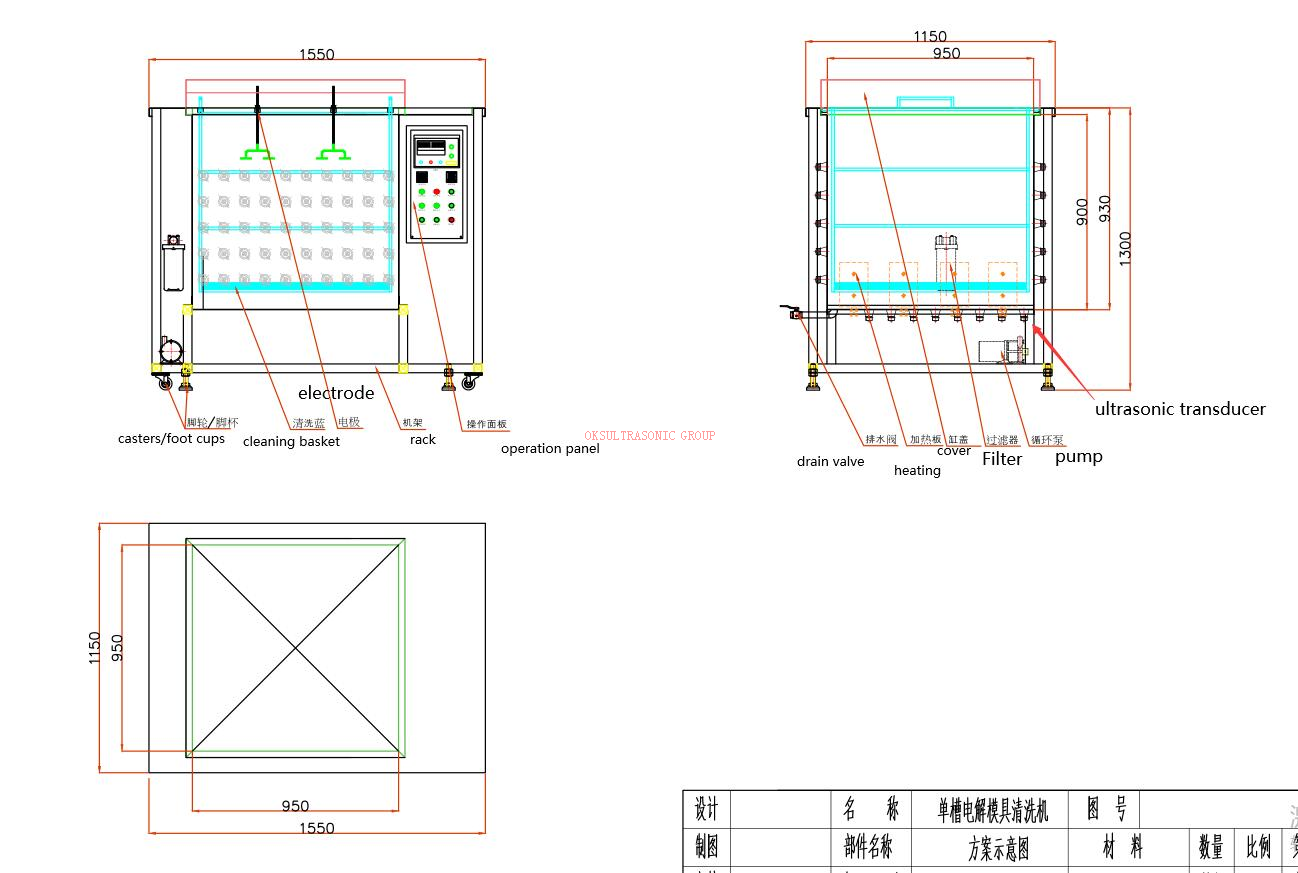

1: Description of cleaning process of electrolytic ultrasonic (plastic mold) cleaning machine

2: Equipment use: used for cleaning precision plastic molds, hardware, modules, modules, mold cores, inserts, inserts, decontamination, high-temperature carbon deposits, sulfides, gas, degreasing, and rust removal.

3. The circulatory system is composed of a corrosion-resistant American little giant magnetic pump and a filter composed of self-circulation, so that the dirt that is washed off is quickly isolated by the filter cotton core, reducing liquid surface floats. At the same time, it can accelerate the electrolysis of the solution. Purify the solution and improve the utilization rate of the solution.

Type

Frequency (Khz)

Power(W)

Capacity(L)

OKS-MJQXJ-18LTT

40KHZ

1000W

18L

OKS-MJQXJ-20LTT

40KHZ

1200W

20L

OKS-MJQXJ-30LTT

40KHZ

1500W

30L

OKS-MJQXJ-40LTT

40KHZ

1700W

40L

OKS-MJQXJ-50LTT

40KHZ

2500W

50L

OKS-MJQXJ-60LTT

40KHZ

3000W

60L

OKS-MJQXJ-70LTT

40KHZ

3600W

70L

OKS-MJQXJ-80LTT

40KHZ

4000W

80L

OKS-MJQXJ-100LTT

40KHZ

5000W

100L

OKS-MJQXJ-115LTT

40KHZ

5200W

115L

OKS-MJQXJ-400LTT

40KHZ

6000W

400L

Using electrolysis, the object produces positive and negative molecules due to the action of electric current. Under the catalysis of oxygen and hydrogen generated on the metal surface, the dirty parts are quickly decomposed, peeled off and surfaced.

Utilizing the cavitation effect of ultrasonic waves, countless small bubbles are generated to collide with the object. Impact blasting the dirt on the workpiece to automatically peel off the dirt.

Using a special solution to make the dirt quickly decompose through a sufficient chemical effect.

The electrolytic ultrasonic system is composed of an ultrasonic generating system, an electrolytic circuit system, a circulating filter system, a control system, a special gold type cleaning fluid and a water-based rust inhibitor.

Ultrasonic cleaning is a process in which a 40KHZ high-frequency power supply is used to make the transducer convert mechanical energy from electrical energy. Tens of thousands of cavitation bubbles are constantly forming explosions, impacting the surface of the cleaned metal object, and quickly detaching the dirt on the metal surface.